Water contamination affects millions worldwide, creating an urgent need for innovative purification methods. Traditional filtration systems often fall short when dealing with complex contaminants or require frequent maintenance that many communities cannot afford. This challenge has led researchers to explore alternative approaches, including magsorption water purification.

Magsorption water purification represents a breakthrough technology that combines magnetic fields with adsorption processes to remove impurities from water. This method offers a chemical-free solution that can effectively treat various types of contamination while maintaining cost-effectiveness and environmental sustainability.

Magsorption Water Purification Technology

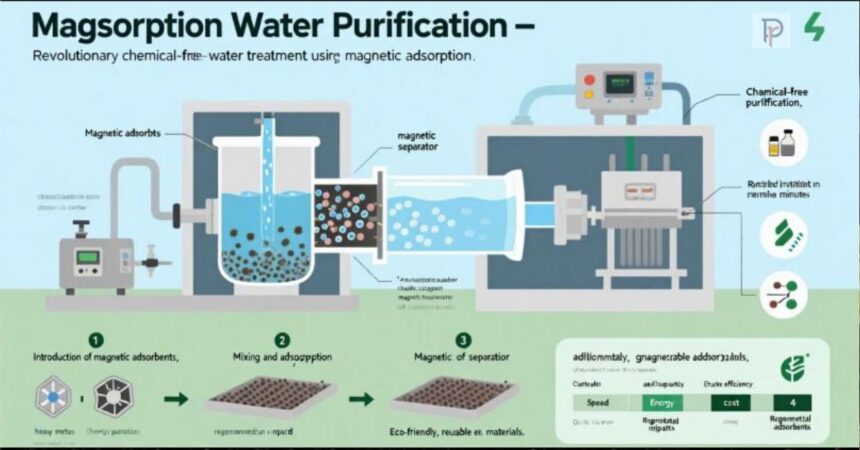

Magsorption water purification is an advanced treatment method that uses magnetic forces to enhance the removal of contaminants from water. The process works by applying controlled magnetic fields to water containing specially designed magnetic adsorbent materials.

These magnetic adsorbents attract and bind with pollutants, heavy metals, and organic compounds present in contaminated water. Once the contaminants are captured, powerful magnets separate the loaded adsorbents from the treated water, leaving behind clean, purified water.

The technology differs significantly from conventional water treatment methods by eliminating the need for harsh chemicals or complex filtration systems. This makes magsorption water purification particularly valuable in areas where traditional treatment infrastructure is limited or unavailable.

How Magsorption Water Purification Works

The magsorption water purification process begins with the introduction of magnetic nanoparticles or magnetic composite materials into contaminated water. These materials are specially engineered to have high surface areas and strong affinity for specific contaminants.

During the mixing phase, the magnetic adsorbents disperse throughout the water and begin capturing pollutants through various mechanisms including ion exchange, electrostatic attraction, and chemical bonding. The magnetic properties of these materials allow for easy separation once the adsorption process is complete.

A high-gradient magnetic separator then removes the contaminated magnetic adsorbents from the water. This separation process is rapid and efficient, typically taking only minutes compared to hours required by traditional sedimentation methods.

Key Components of Magsorption Systems

Magsorption water purification systems consist of several essential components that work together to achieve effective water treatment. Understanding these components helps explain why this technology offers superior performance compared to conventional methods.

The magnetic adsorbent materials form the heart of the system. These can include:

- Iron oxide nanoparticles coated with activated carbon

- Magnetic biochar composites

- Functionalized magnetic polymers

- Magnetic ion exchange resins

- Hybrid magnetic-photocatalytic materials

READ MORE: Complete Guide to Filma Avloppsrör: Modern Sewer Pipe Inspection Made Simple

| Component | Function | Advantages |

| Magnetic Adsorbents | Capture contaminants | High surface area, selective binding |

| Mixing Chamber | Ensure contact between water and adsorbents | Optimized residence time |

| Magnetic Separator | Remove loaded adsorbents | Rapid separation, high efficiency |

| Control System | Monitor and adjust process parameters | Automated operation, consistent results |

| Regeneration Unit | Restore adsorbent capacity | Cost reduction, sustainability |

Applications of Magsorption Water Purification

Magsorption water purification technology shows remarkable versatility across different water treatment applications. Industrial facilities use this technology to remove heavy metals from wastewater before discharge, ensuring compliance with environmental regulations while reducing treatment costs.

Municipal water treatment plants have begun incorporating magsorption systems to address emerging contaminants that traditional methods struggle to remove. These include pharmaceutical residues, endocrine disruptors, and complex organic molecules that pose health risks even at low concentrations.

Agricultural applications represent another growing area where magsorption water purification proves valuable. Farmers use these systems to treat irrigation water, removing salts and harmful chemicals that could damage crops or contaminate food supplies.

Advantages Over Traditional Water Treatment Methods

Magsorption water purification offers several significant advantages compared to conventional treatment technologies. The speed of treatment stands out as a major benefit, with complete purification cycles often completed in minutes rather than hours.

Energy efficiency represents another key advantage, as magsorption systems require minimal power consumption compared to membrane filtration or UV disinfection systems. This makes the technology particularly suitable for remote locations or areas with limited energy infrastructure.

The chemical-free nature of magsorption water purification eliminates concerns about residual chemicals in treated water. Traditional methods often leave traces of chlorine, aluminum, or other treatment chemicals that can affect taste and potentially impact health over time.

Cost-effectiveness becomes apparent when considering both initial investment and ongoing operational expenses. While the upfront costs may be comparable to conventional systems, magsorption technology typically requires less maintenance and has lower consumable costs.

Environmental Impact and Sustainability

Magsorption water purification aligns with growing environmental concerns and sustainability goals. The technology produces minimal waste compared to conventional treatment methods, as the magnetic adsorbents can be regenerated and reused multiple times.

The absence of chemical additives eliminates the environmental burden associated with chemical production, transportation, and disposal. This reduction in chemical usage also decreases the carbon footprint of water treatment operations.

Magnetic adsorbents can often be produced from waste materials or renewable resources, further enhancing the environmental benefits. Some systems use magnetic biochar made from agricultural waste or magnetic composites derived from recycled materials.

Challenges and Limitations

Despite its promising advantages, magsorption water purification faces certain challenges that limit widespread adoption. The initial cost of magnetic adsorbent materials can be higher than conventional treatment media, though this is often offset by longer service life and regeneration capabilities.

Technical complexity requires skilled operators and proper maintenance protocols to ensure optimal performance. Rural or developing regions may lack the technical expertise needed to operate and maintain these systems effectively.

Scale-up challenges exist when transitioning from laboratory demonstrations to full-scale industrial applications. Engineering considerations such as mixing efficiency, magnetic field distribution, and separation kinetics become more complex at larger scales.

Future Developments and Research Directions

Research in magsorption water purification continues advancing rapidly, with new magnetic materials and system designs emerging regularly. Scientists are developing more selective adsorbents that can target specific contaminants while ignoring harmless substances naturally present in water.

Smart magsorption systems incorporating artificial intelligence and machine learning are under development. These systems will automatically adjust operating parameters based on water quality changes and predict maintenance needs before problems occur.

Hybrid systems combining magsorption with other treatment technologies show promise for addressing complex contamination scenarios. Integration with membrane filtration, advanced oxidation, or biological treatment processes could expand the range of applications.

Economic Considerations and Market Potential

The global market for magsorption water purification technology is experiencing steady growth as awareness of its benefits increases. Cost analyses demonstrate favorable economics for many applications, particularly when considering total lifecycle costs rather than initial capital investment alone.

Government incentives and environmental regulations increasingly favor technologies that reduce chemical usage and minimize environmental impact. These policy drivers create favorable conditions for magsorption technology adoption across various sectors.

Private investment in magsorption research and development continues growing as companies recognize the commercial potential. This investment accelerates technology development and helps reduce costs through economies of scale and manufacturing improvements.

Installation and Maintenance Requirements

Magsorption water purification systems require careful planning during installation to ensure optimal performance. Site preparation must consider factors such as power supply, water flow rates, and space requirements for system components.

Regular maintenance focuses primarily on monitoring magnetic adsorbent performance and conducting periodic regeneration cycles. This maintenance is typically less intensive than conventional systems, as there are fewer mechanical components and no filter replacements required.

Training requirements for operators are moderate, focusing on understanding magnetic separation principles and system monitoring procedures. Most manufacturers provide comprehensive training programs to ensure proper system operation and maintenance.

Conclusion

Magsorption water purification represents a significant advancement in water treatment technology, offering chemical-free, efficient, and environmentally sustainable solutions for various contamination challenges. As research continues and costs decrease, this technology is poised to play an increasingly important role in global water treatment infrastructure.

The combination of rapid treatment times, low energy requirements, and minimal environmental impact makes magsorption an attractive option for communities seeking reliable water purification solutions. While challenges remain in terms of cost and technical complexity, ongoing developments suggest these barriers will continue diminishing over time.

For organizations considering water treatment options, magsorption technology deserves serious evaluation, particularly for applications involving heavy metal removal or complex organic contaminants that challenge conventional treatment methods.

Frequently Asked Questions

Q: How long do magnetic adsorbents last before needing replacement?

A: Magnetic adsorbents can typically be regenerated and reused 50-100 times before replacement, lasting 2-5 years depending on water quality and usage.

Q: Can magsorption systems handle high-flow industrial applications?

A: Yes, magsorption systems can be scaled up for industrial flows, though larger installations require careful engineering of mixing and separation components.

Q: Is magsorption effective against biological contaminants like bacteria and viruses?

A: While primarily designed for chemical contaminants, some magnetic adsorbents can capture microorganisms, though additional disinfection may be needed for complete biological treatment.

Q: What happens to the captured contaminants after magnetic separation?

A: Captured contaminants are typically concentrated through adsorbent regeneration processes, allowing for proper disposal or potential recovery of valuable materials.

Q: Are there any safety concerns with magnetic fields in water treatment?

A: The magnetic fields used in magsorption systems are generally considered safe, similar to those in MRI machines, and pose no health risks to operators or consumers.